Services

Design & Engineering

RMFI offers design engineering assistance to our valued customers.

Our on-site engineers and production specialists will work with you throughout the development of your designs to effectively achieve your cost, performance and volume requirements

- New product design and development assistance

- Rapid Prototyping – enables improved functional performance through rapid iterations in the design phase.

- Project Management with an integrated Project Team Approach

- Turnkey focus

RMFI can help you meet your project’s specific requirements, budget and schedule.

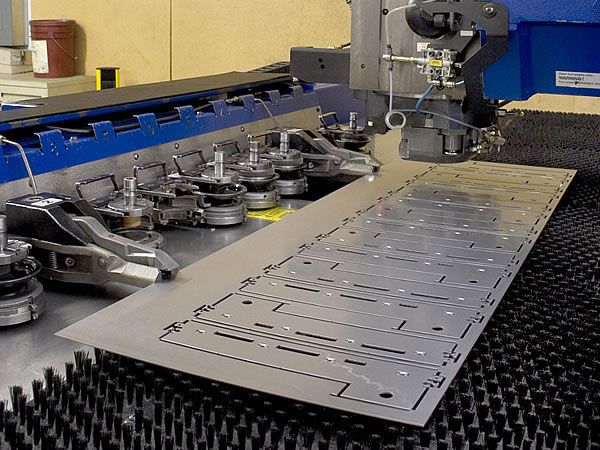

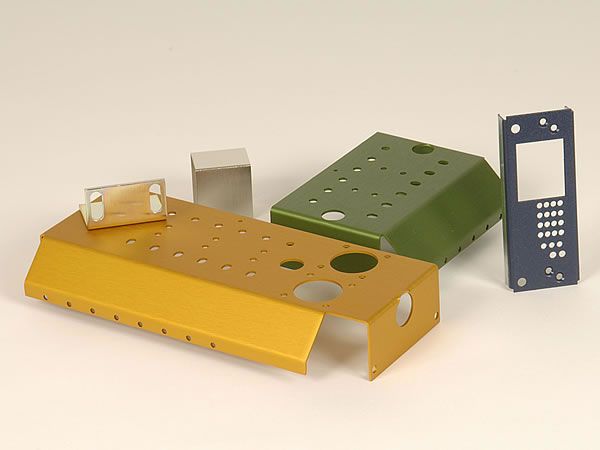

Punch, Laser Cutting & Forming

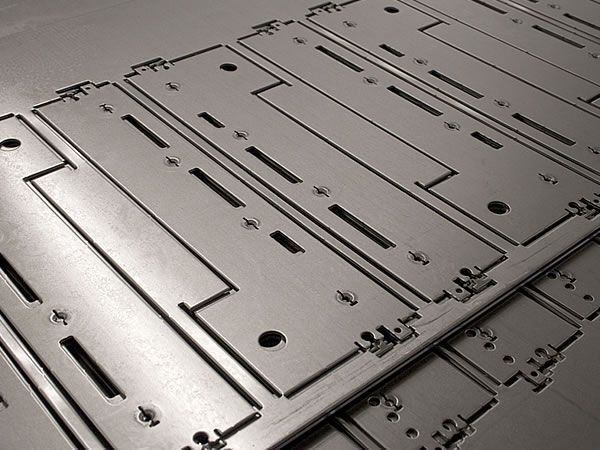

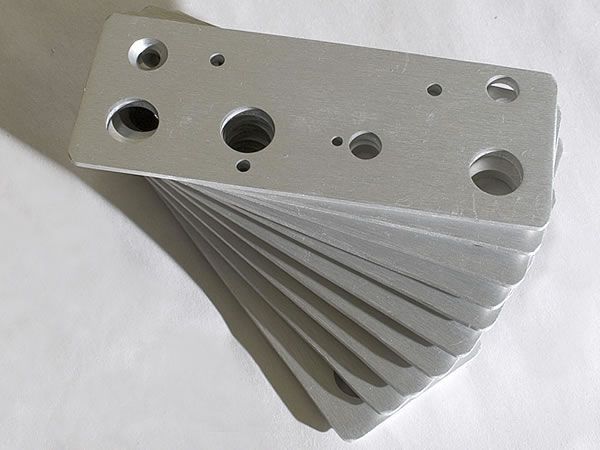

PUNCHING & LASER CUTTING

The most modern CNC laser cutting and punching systems are used to punch, cut, and separate the parts from the sheets. These machines are highly accurate, fast, and can be re-programmed whenever a part may be revised. We have hundreds of unique tools and dies in our inventory. This allows us to produce small or large quantities efficiently usually without NRE charges or extra tooling costs. Laser cutting is fast and flexible requiring no tooling and capable of complex shapes.

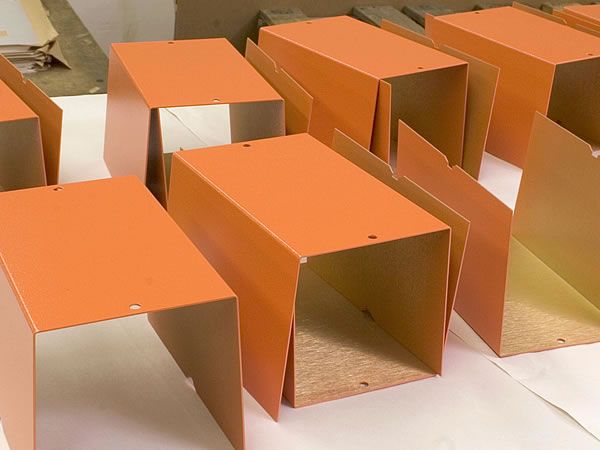

FORMING

Our CNC-Press brakes are used to bend parts to meet the precise dimensions shown on the drawings. These machines are highly accurate, fast, and consistent in operation. Customer drawing files are maintained in our server to facilitate rapid set-ups for production jobs.

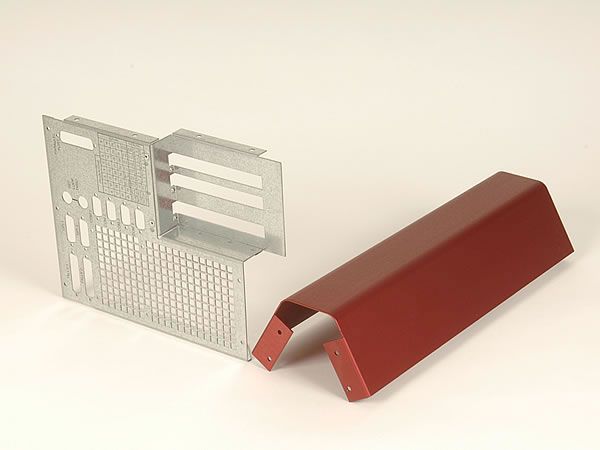

Finishing

Painting, and Silk Screening – In House and On Time.

Our in-house paint shop provides our customers with the finest Class-A painting capabilities for highly cosmetic parts.

Our in-house silk-screening shop produces exceptional results on parts, ranging from the simplest one-color design to complex multi-color designs.

RMFI has the capabilities to process hundreds of parts in just a few hours. We would like the opportunity to provide our services on your next production job.

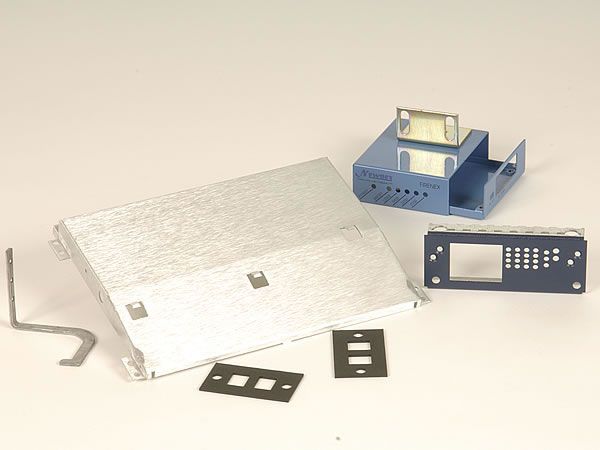

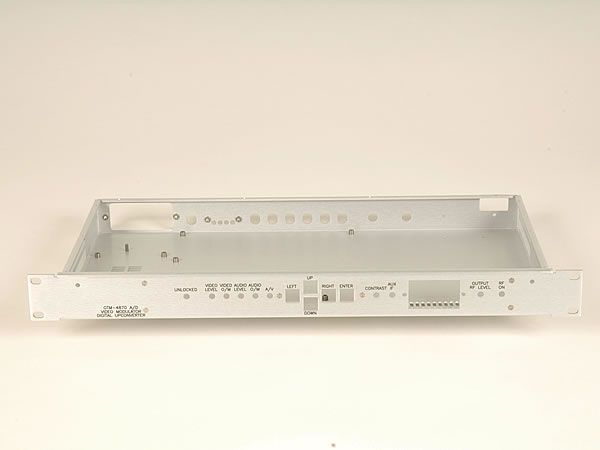

Value added Assembly

RMFI offers value-added assembly services to save customers time and money. We will take responsibility for mechanical assembly into enclosures that RMFI fabricates. This turnkey process gives customers a single point of purchase, resulting in quick, flexible and cost-effective production of assemblies that are complete and ready to use. Each operation is custom-designed depending upon the product and application.

All equipment we produce passes through various levels of subassembly and final assembly, testing and inspection checks. Our final assembly area with dedicated production lines was established for the integration of the various components in the final assemblies.

Value added Assembly

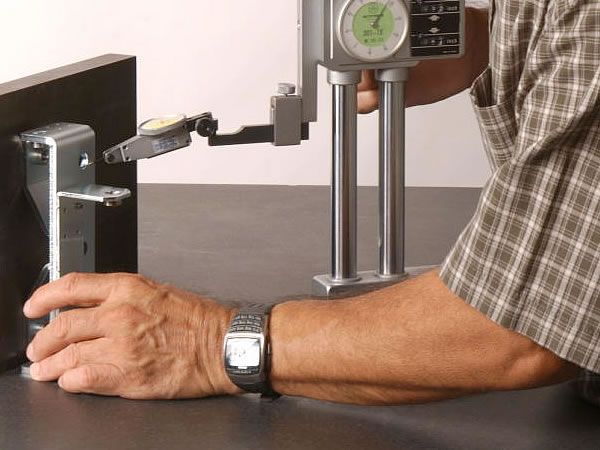

Quality is a very important part of the fabrication process. RMFI is a certified ISO 9001:2008 company.

This requires that a strict inspection procedure be utilized at every operation in the production process. First piece inspection is done for each step of production, and certificates of compliance are available when requested.

Packaging & Delivery

Packaging

RMFI’s final process is packaging the finished product so it can be sent on its way.

Delivery

We utilize our own fleet of vehicles to provide local delivery of parts. We work closely with the larger carriers for long-distance shipments. All to insure your parts are delivered save and when you need them.

Now how can we help you?

Call (408) 734-0713 to find out.

Or request a quote on the right if you think you're ready with all the details needed to quote your job. If we have questions, we'll call you.

ISO 9001-2008 Certified